Quanzhou DAFON Machinery Co.,Ltd.

Mob :+86 15059560663

Website:feibao.cc

Add: Hailian Industrial Park, Shuitou Town, Nan'an City, Fujian Province, China

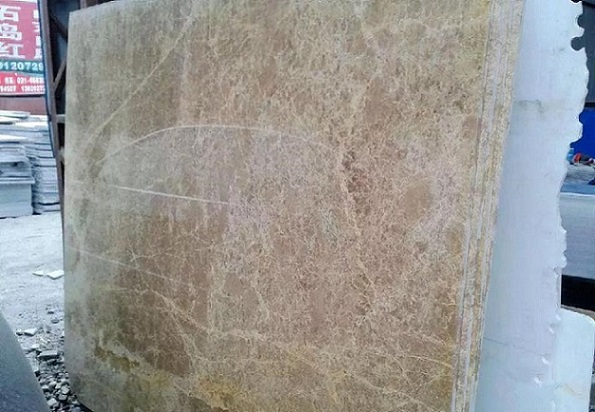

When encountering marble chromatic aberration, people's first reaction is to be afraid, always eager to eliminate chromatic aberration or hope to choose marble with smaller chromatic aberration. In fact, marbles with chromatic aberration are precious. The greater the chromatic aberration, the more precious it is.

Reason one: Surface mines and deep mines

The stone is mined in batches from the mine, from top to bottom, from outside to inside. In the natural environment, the outer stone is more exposed to water, air, and sunlight. The stone hidden in the interior has no such environment. Therefore, there is a general difference in color between surface ore and deep ore. After the deep ore is mined, the stone will also change under the new environment such as sunlight, air, and water, resulting in a difference in color.

This four heads engraving machine is suitable for batch engraving, engraving 4 pieces of the same pattern at the same time, high efficiency. Villa home decoration exterior wall carving, TV background wall carving, tombstone relief carving, railing board relief, temple ancient building carving, hollow carving, special-shaped lines, granite bluestone marble, and other stone carvings

DAFON popular product is stone cutting line for kerbstone/curbstone/paverstone, bridge block cutter, Infrared cutting machine, stone splitter, chamfering grinding machine, automatic edge cutting machine, bush hammer machine, polishing machine, quarry equipment, stone crushing machine and so on.

Reason two: different mining and processing methods

Stones mined from mines are usually whole blocks, which need to be cut into pieces, which we call big slabs. In the processing of blocks, there are different cutting directions. This kind of processing difference, even if you pay attention to stone processing, cannot be completely avoided. The cut plates will have more or fewer differences.

Reason three: The degree of surface processing is different

For the same stone variety, the color of the rough surface and the smooth surface are different. In the smooth surface, the difference between polishing to 10 degrees and polishing to 50 degrees, 70 degrees, and 90 degrees is also very obvious. The brighter the stone is, the more obvious the pattern and color of the stone will be, and the brighter it will be; while the rough surface will have a hazy beauty.

Contact:

Daisy Huang

Whatsapp&wechat:+86 18859970759

Email:daisy@dafonmachine.com

Website:dafonmachine.com